Rail Maintenance Machines

-

Designed around the needs of the owner-operator, the TLB890 side shift backhoe loader is a powerhouse of productivity delivering impressive levels of reach and dig depth with fast cycle times and greater economy. A heavyweight in terms of productivity with high breakout forces and lifting capabilities, the TLB890 side shift backhoe loader is ideally suited to the widest range of applications including civil engineering, highway construction & maintenance, utilities, and agriculture. Delivering faster cycle times and greater economy while returning a high residual value, the TLB890 helps your business increase its return on investment.

Optional Attachments:

- Pallet Forks

- High-Tip Bucket

- Loader Quick Attach

- Farm Fork and Grapple

- Broom Bucket

- 7-in-1 Bucket

- Hydraulic Breaker

- Excavator Quick Attach

-

The VHR235 Hi-Rail Excavator is the best combination of power and size allowing you to tackle all your medium and large-scale MOW projects in one easy-to-use machine. With the in-cab upgraded HMI attachment management system, you can utilize all current and newly developed MOW attachments. This model is more cost-effective and offers the same great enhancements of increased productivity, comfort, low fuel consumption, and ease of operation.

FEATURES

•Tiltrotator

•LCD monitor

•Tool control system

•Air conditioning

•Hi-rail operator cab controls

•FRA approved braking system

•Rear cameraAVAILABLE ATTACHMENTS

•tinbin Dry vac

•Rail Threader

•Tie Tampers

•Tie Inserters

•Under-Cutter Bars

•Brush Cutters

•IMR Tie-Exchanger

•IMR Panel Carrier -

CHR313-C This is the perfect addition to our rail equipment line. Compact in design, the CHR313-C hi-rail excavator features great strength and performance in a lighter-weight machine. The advanced hydraulic system of the compact CHR313-C allows the operator to work on- and off-track –but delivers performance that is unmatched for its size.

HI-RAIL

The hydraulically powered hi-rail function of the hi-rail excavator allows for easy adjustment when switching from off-track, to rail and track travel.

ENGINE

The CHR313-C is powered by the industry leading Cat C4.4 with ACERTTM technology with consistent high performance rating and unmatched fuel efficiency.ATTACHMENTS

Engineered with priority flow hydraulics, the CHR313-C3 can operate an extensive line of attachments and specialized railroad tools for compact machines that handle the demands ofFEATURES

- Hydraulic Quick Coupler

- LCD Monitor

- Tool Control Systems

- Vandalism Guards

- High Ambient Cooling Capacity

- Air Conditioning

- Full Hi-Rail Operator Cab Control

- FRA Approved Braking System

- Rear Camera

-

CHX20E Hi-Rail Excavator is easy to maneuver, yet powerful enough to tackle demanding MOW projects. The enhancements made to this model offer increased productivity and comfort, less fuel consumption and ease of operation. Add in the ability to couple to a variety of attachments and the CHX20E allows you to tackle all your medium and large scale MOW projects in one easy-to-use machine.

As rail lines see increased traffic, the ability to schedule track windows for MOW projects is decreasing. Hi-rail products are designed to exit any non-crossing locations to make way for oncoming train traffic. This allows for full utilization of track lines and can keep rail MOW projects on schedule.

FEATURES

- Hydraulic Quick Coupler

- LCD Monitor

- Tool Control Systems

- Vandalism Guards

- High Ambient Cooling Capacity

- Air Conditioning

- Full Hi-Rail Operator Cab Control

- FRA Approved Braking System

- Rear Camera

- Reduced Radius

-

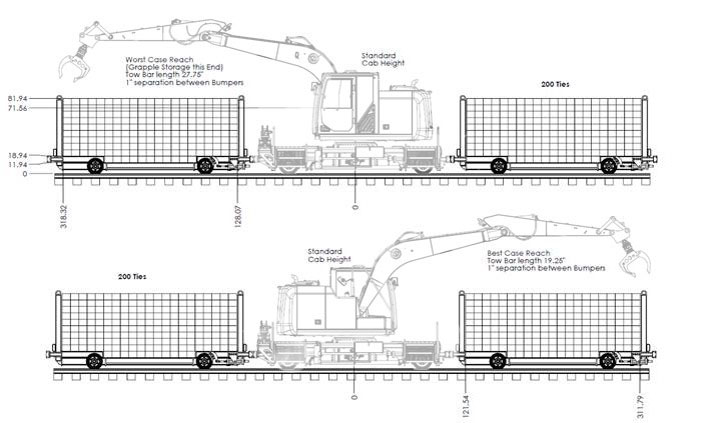

- High Capacity Tie Cart – Primary

- Cart holds 201 Railroad Ties

- Holds 2 Tie Work heads

-

Mecalac rail-road excavators are the ideal solutions for users in need of a compact machine with high performance. Every part of the machine is specifically designed to boost the weight-to-performance ratio.

The 106MRail is the smallest end of our MRailproduct line. In this size and with such ease of use, it’s the perfect utility machine to support larger equipment. The standard offset boom along with the overall compactness of this model make it a very handy tool for all light applications in urban environments (subways, tramways, ...) and for working in tunnels or tight areas. The 106MRail is an easy goer; easy to get on and off rail, easy to operate, and easy to move with less impact on the ballast.

-

Mecalac rail-road excavators are the ideal solutions for users in need of a compact machine with high performance. Every part of the machine is specifically designed to boost the weight-to-performance ratio.

Like the 106MRail, the 136MRail is a very handy tool for all light to medium applications in urban networks and for working in tight areas. Plus it boosts your overall productivity, also in national networks, with the utmost safety devices to meet the most stringent regulatory standards. The outstanding lifting and towing capacities along with the ability to work as a loader, spreading large buckets of ballast for instance, will boost your overall productivity. Now you can work faster, for all types of service works and maintenance on rails.

-

Mecalac rail-road excavators are the ideal solutions for users in need of a compact machine with high performance. Every part of the machine is specifically designed to boost the weight-to-performance ratio.

Strong machines to complete all the hard tasks in a minimum of time but also with a maximum of constraints around. If you don’t want to jeopardize your maneuverability and agility against force, then the 216MRail is made for you. The 216MRail excavator is here to offer you a new alternative: that of agile strength will give you the freedom of movement you are longing for.

-

The NMC CMC12E Magnetic Crane was designed specifically for railroad material handling maintenance and transport projects. This machine combines agility and strength to tackle the most demanding material handling jobs with a variety of attachment options. It’s ideal for jobs that require both on-track accessibility and transport. The Magnetic Crane is highly maneuverable and effectively couples with a hi-rail maintenance scrap cart. This allows operators to safely handle and transport material on-track.

Features:

- LCD Monitor

- Tool Control Systems

- Vandalism Guards

- Air Conditioning

- High Ambient Cooling Capacity

- Scrap Cart Towing Package Option

Options

- Magnet

- Buckets

- Thumbs*

- Grapples

-

Features

- Automatic Mode and Manual Mode Weld Grinding

- Two Independent Workheads For Grinding On Either Rail

- Grinding Length of 3’ For Easy Transition Rail Grinding

- Water Tank for Prewetting and Fire Prevention

- Spark Curtains Around Workhead for Spark Retention

- Uses Standard 6” – 6000 rpm Cupstones

- 24 Volt Machine

- Center Pick

- 3” Solid Steel Axles

- Pivoting Rear Axle

- Dual Axle Parking Brakes – 4 Wheel Brakes

Options

- Turntable with mechanical and electrical interlock as per specifications

- Two "Jump Seats", one on each side of operator that flip up against back wall

-

This machine offers a modern approach to railroad tie handling. The CTC08E Tie Crane’s compact design packs a powerful lift capacity and precise tool control which delivers enhanced tie handling agility. Operators can work efficiently with railroad concrete and wood ties as well as other material handling applications. The on-track drive of the machine allows for greater visibility and enhanced tie placement accuracy

Features

- LCD Monitor

- Tool Control Systems

- Vandalism Guards

- Air Conditioning

- Ergonomic joysticks

- COMPASS display panel

- Dynamic operator sound pressure 70 dB(A)

- Average exterior sound pressure 99 dB (A)

- High Ambient Cooling Capacity

- Air Suspension Seat

- Load Sensing Hydraulic Coupler

- Tier 4 Final Engine

- 11RMP Swing

- No DEF Fluid Required

Options

- Tie Head for tie material handling

-

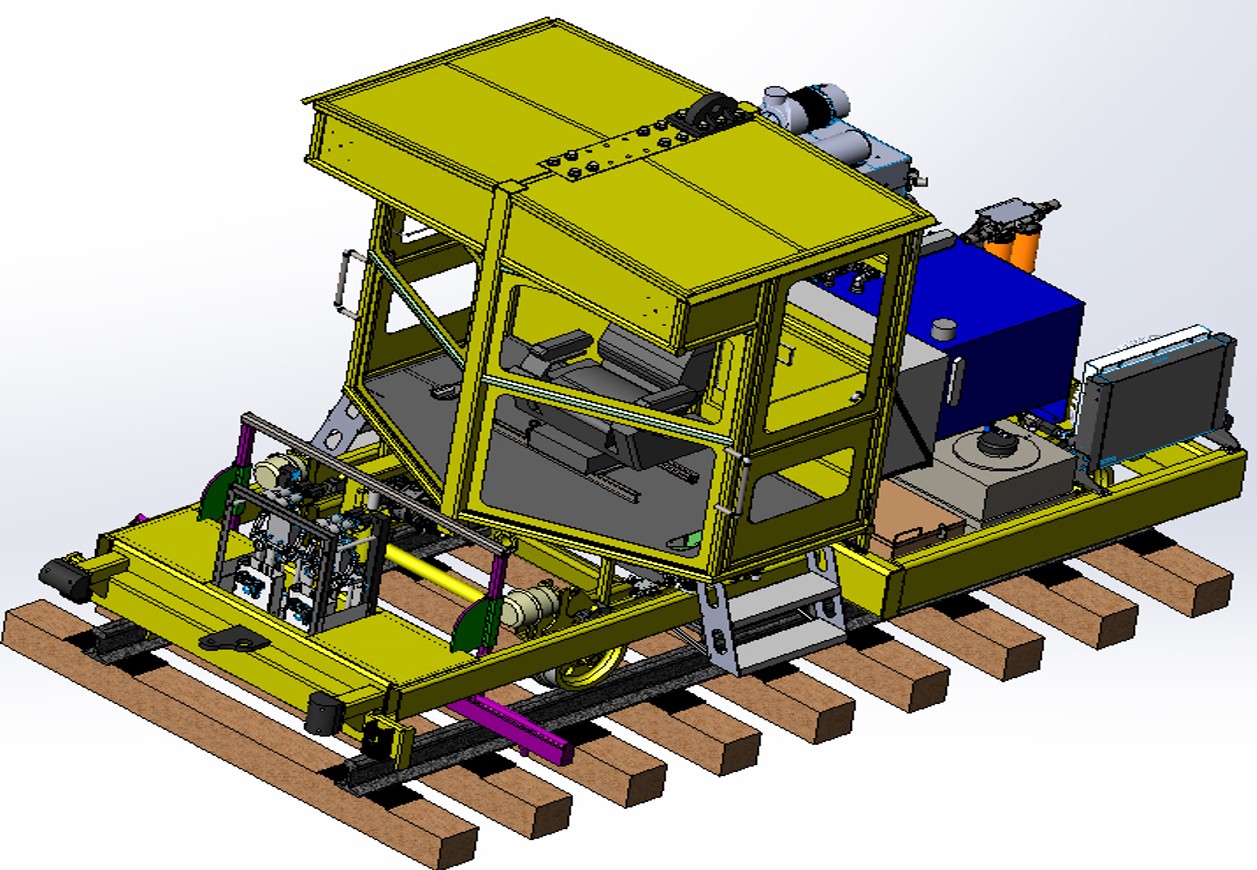

Features

- We do not take exection to any of the specification and intend to be compliant with all Self propelled tie marking machine capable of marking ties with water based paint on the inside or the outside of both rails with operator direction using a control panel (push button).

- Machine weight approximately 14,000 lbs

- Kab 525 Seat with seat belts

- Currently utilizing a 99 hp turbo charged diesel engine

- Cab enclosed with pressurizer and MacBone heat and air conditioning

- 2" non-insulated axle with cast (not stamped) wheels

- LED lighting for travel, brake and work lights all around

- Windshield with safety glass as per specifications

- Cab to be designed with operator's view of ties directly in front of cab area in mind such that the operator will be able to clearly see the ties in front of the cab and will be easily able to determine the tie to stop at and paint

- Interior cab lighting per specification

- Hydraulic drive system capable of 25 mph and up a equipment loading ramp and up a 2% grade

- 4 wheel drive via two motors on solid axles

- Hydraulic oil reservoir to be size and cooler capable of adequately cooling oil to allow machine operation during summer months utilizing AKG cooling components.

- Air fail-safe brakes, service and parking

- Fuel tank sized for 12 hours day

- Machine to have pivoting axle if over 10' wheelbase, current machine design is under 10'

Options

- Turntable with mechanical and electrical interlock as per specifications

- Two "Jump Seats", one on each side of operator that flip up against back wall

-

- Hatz Diesel Engine – 3 Cylinder “Silent Pack” High Output

- Dynamic Braking

- Hydraulic Drive Motor with Hydraulic Fail-Safe Brake

- Heavy-Duty 10,000 lb. Axles

- Pump Has Built-in Relief and Flow Divider

- Remote Axles Grease Zerks

- Drive System: Self-propelled at walking speed, hydraulic with manual clutch engagement

- Control: From operator’s position – push button, and disengage clutch to tow

- Tool Circuit: 1-10 GPM circuits at 2,000 PSI capable of operating two tools independently

- Tools Booms: Two independent booms which pivot from a single center support post supporting the tools at zero weight.

- Tools and Boom Storage: The tools and booms store in holders to lock them in place for transport

-

- Self Propelled Tie Plate Gager

- (Fully Automated Mode, tethered remote)

- Machine to index in work mode on 4 ply type rubber wheels

- Diesel Engine powered

- In Fully Automated Mode, the operator will simply walk along with machine only stopping for plates missed due to poor tie conditions.

- Machine will travel and (with limit switches and /or proximity sensors) find tie edge and cycle automatically and then move to the next set of three ties.

- In Manual Mode, the operator will cycle the plate arm manually at walking speed using tethered remote. (Forward, Reverse, Stop, Cycle)

- Machine will cycle out and drag three tie plates into gage plate and into position.

- Hydraulic cylinder extension with three independent gage plates to catch tie plates and move into position (adjustable for different plates)

- Machine to be towable via wheels for towing mode.

- Gage of pregaging to be adjustable with hydraulic cylinder

- BNSF Tow Eye and Bumpers

-

This is the perfect addition to our rail equipment line. Compact in design, the CHX12E hi-rail excavator features great strength and performance in a lighter-weight machine. The advanced hydraulic system of the compact CHX12E allows the operator to work on- and off-track – but delivers performance that is unmatched for its size.